Hatches connect the lower levels of the wind turbine structure and the platform decks.

Used frequently, improper maintenance of access hatches is a major safety risk and is commonly mitigated through the O&M schedules and procedures.

Yet, the responsibility shouldn’t fall on the O&M procedures alone.

As a leading provider of gate and hatch hardware to the offshore industry, we understand the many challenges faced by asset owners and operators around the safety, installation and maintenance of platform hatches.

Many of these challenges surround the operational health and safety of personnel working around and on hatches combined with the wasted time, resource and cost of complicated maintenance programmes, untimely replacements and the requirement to rectify improper use of hardware. At Gatemaster Offshore we provide a number of solutions to meet these health and safety and operational challenges.

In this article, we will focus on how you can improve offshore safety with hatch hardware while also significantly reduce time spent on O&M.

How to improve offshore safety with hatch hardware

Some of the main safety risks associated with platform hatches are:

- Falling through an open hatch

- Tripping over hatch fittings including hinges

- Injuries sustained while operating/opening/closing the hatch.

In addition to this, there are the challenges associated with O&M:

- Loss of time due to spent on untimely replacements needed

- Wasted time due to complicated maintenance procedures

- Complications arising due to improper hardware being used

There are a few ways you can reduce the safety risks commonly associated with hatches by installing the right hardware and following recommended maintenance procedures.

Falling

Use hatch hardware that is easy and safe to close. This way you can avoid operators leaving the hatch open even for a little while. If the hatch is unsafe to close, an operator might choose to leave it open while they perform some short-term work on the platform as this is the easiest.

Consider using foot operated mechanism to close the hatch after use. A foot operated lever for instance, makes it less likely that an operator will fall down the hatch due to leaning over it trying to release the hatch.

Flush fittings: We will discuss this more later, but using flush fittings and fixings means fewer trip hazards, and therefore less stumbling and falling while on deck.

Trip hazards

As mentioned above, trip hazards are a common cause of injuries and loss of work time on offshore platforms/rigs.

Operators are already working in a tricky environment, where they are exposed to the elements. Trip hazards should be the last thing on their mind when going about their jobs.

Luckily, you can get hardware for offshore hatches that are installed as flush with the grating/floor as possible. Like our hatch handle or hatch hinge, which we will present in more details below.

Injuries

There are a lot of ways you can sustain an injury while onboard an offshore structure. For hatches injuries like trapped hands, feet, or worse are common due to improperly functioning hardware or difficult closing mechanisms that are hard to operate safely.

A good step is to consider the placement and usage of the hatch. This can help you determine if a foot-operated or hand-operated release is best. In some cases, a foot-operated lever is best as it means the operator doesn’t have to lean over or down to release the hatch.

Another injury to avoid is of course head injuries. Although PPE and helmets are worn on offshore platforms, a hatch to the head is best to avoid. Using a sturdy hatch catch (like the one we show you further on) will hold the hatch open, allowing the operators to climb in and out without the fear of a hatch falling. It makes for better work practices as well, as operators don’t have to use one hand to hold the hatch open while climbing out.

Hatch hardware solutions

The hatch handle

It is a common misconception that the term ‘marine grade’ makes a product suitable for offshore use. Unfortunately, settling for substandard hardware is seen often in the industry due to lack of available products designed specifically with offshore access hatches in mind.

Using hatch handles as an example, handles for boat hatches are commonly used. These are often made from a seemingly durable plastic to make them suitable for the highly corrosive environment. The issue at hand is linked to the strength of such handles. Hatches on boats weight considerably less than an offshore access hatch and experience less stress and weight. Using a standard boat hatch handle on a heavier GRP hatch is therefore a recipe for continuous replacements.

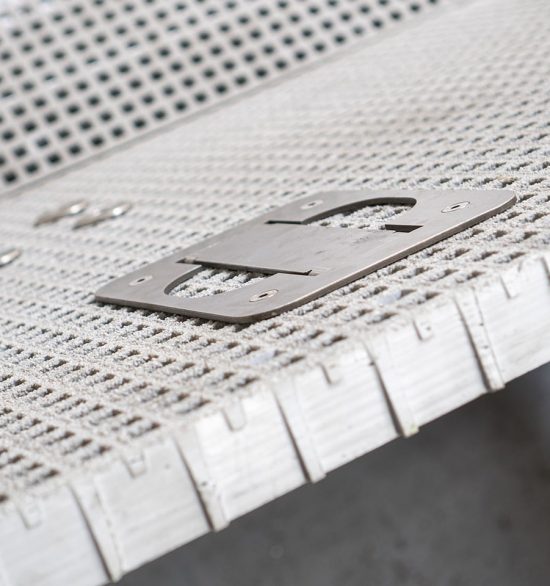

To provide a suitable solution, we have made a hatch handle made specifically to carry the weight of the heavy GRP hatches on offshore platforms and rigs.

| Simple pull mechanism for easy operation | Flush fittings meaning no trip hazard |

| Adaptable fixings to fit any GRP as they bolt on | Easy and simple for O&M to maintain |

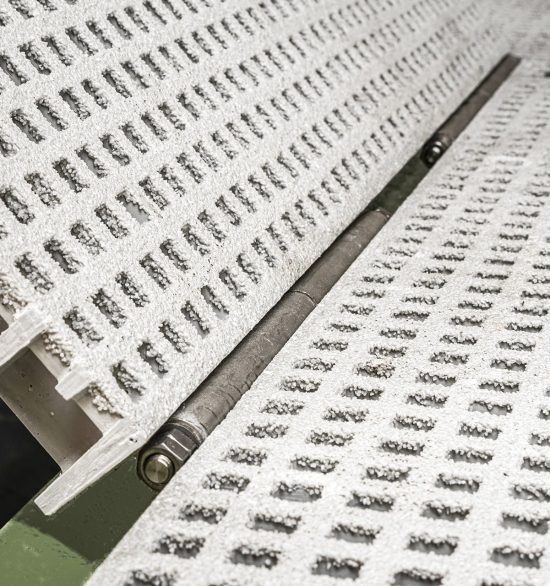

The hatch stay

One way to alleviate some of the risk associated with hatches is to install hatch stays, which ensure the hatch stays in open position when operators are climbing in and out of the hatch. But hatch stays like this one below, has a few more benefits that just holding the hatch in place:

| Hold the hatch open to minimise risk of injury | Foot operated – no leaning over needed to operate |

| Spring assisted dampener to avoid using hydraulics offshore – O&M is easier with mechanical components only | Fixing require no routing or welding as they clamp on the grating |

| Can be handed and adjusted to suit most set-ups | Easy installation and maintenance |

| Keeps the hatch from opening too far to avoid damaging railings or adjacent fixtures/people around. |

The hatch catch

Similar to the hatch stay, this hatch catch makes sure the hatch doesn’t fall down unexpectedly while in use. The simple installation also makes sure it isn’t too complicated to install or maintain.

| Hold the hatch open to minimise risk of injury | Easy to operate with gravity catch – no leaning over needed |

| Simple bolt-on installation meaning no time wasted on complicated fitting | Suitable to use in combination with our gate hinge |

The hatch hinge

Hatch hinges are another component that is often overlooked in the design process of the platforms. However, an ill-suited hinge can cause a lot of problems for the hatch in terms of function and reliability. Additional features like flush fitting and easy installation can make a world of difference to the O&M team.

| Flush fittings meaning no trip hazard | No welding or routing needed |

| Easy maintenance and replacing if needed | Suitable to use in combination with our gate hinge |

With gate hardware that can be installed easily on different grades of GRP and other materials as well, you can use the same mechanism across the entire platform structure. Using the same mechanisms means you can have the same O&M practices and procedures across the entire platforms, which makes it more efficient for the O&M team thanks to the consistency in the processes.

Want to know more about how to improve offshore safety with hatch hardware? Reach out to our team for more insights:

Looking to find out more? We’d love to hear from you!