Offshore gate hardware has traditionally comprised of amended hardware designed for land use. However, simply improving existing gate hardware to ensure it merely can survive the marine environment isn’t quite sufficient long term and can worsen the daily operation on the platform.

Opting for gate hardware specifically designed for offshore use is a way to eliminate risks and improves the functionality of the gates, ultimately creating a safer environment.

Offshore vs. onshore gates

Operational requirements for offshore gates are typically very different to a traditional land-based gates and has entirely different risks associated with it. The main purpose of a gate on land is to restrict access. Offshore gates not only restrict access but also act as an additional safety barrier for the on-board personnel.

Often, offshore gates need to be held open to allow the transfers of crew members and materials. In addition, any damages to railings and adjacent fixtures are far more costly to resolve offshore.

We dive more into the differences between onshore and offshore gate hardware in this blog. For now, we will focus on how adding certain mechanical functions in your offshore gate hardware improves the functionality on offshore gates and railings.

Improve functionality with the right offshore gate hardware

Existing hardware for onshore gates isn’t fully equipped for these specific offshore requirements as there generally aren’t any need for these functions. It is possible though to use the principles of existing gate closers and re-engineer them to work on offshore platform gates. Two features that make a tremendous difference are the gate stopper and a hold-open function.

What is a gate stopper and why is it important?

The main job of a gate stopper is to prevent gates from swinging too far when opened. A gate stopper will stop the gate and save the railings from impact, which can lead to damages to the structure and fixtures.

Usually, a separate stopper is fitted onto the railings or installed on the platform deck. Although this effectively stops the gate, they can be trip hazards for operators and is yet another component that needs to be fabricated, installed, and maintained.

Integrating the gate stopper in a self-closing hinge eliminates all that. We have therefore engineered our solution with a stopper function that automatically kicks in at a specified angle. The beauty of this is that the angle can be amended depending on the design of the platform.

What is a hold-open function and why is it important?

To make offshore gates safer, they are often fitted with a gate closer or self-closing hinge such as this one. However, having a gate swinging back at you constantly is not just annoying, but a safety risk. As mentioned earlier, there are times when the gate needs to be help open for a period of time to better facilitate crew and material transfers.

Traditionally, solutions for this have included drop bolts or latches to hold the gates open. These solutions create trip hazards and the need to obtain and maintain this additional hardware. On offshore platforms we want to eliminate risks, not create them.

At Gatemaster Offshore we’ve done that by incorporating a hold-open function in our spring-assisted closing hinge. This not only makes the platform access points safer, but also easier to use.

How can offshore gate hardware improve functionality on offshore platforms?

The combination of an integrated gate stopper and hold-open function means operators won’t have to worry about damaging the railings and fixtures, securing the gate during crew transfers or being struck by a closing gate on a daily basis. When the hardware is made in the correct corrosion-resistant materials, the functionality of the gates are maintained for longer too.

Opting for specifically designed offshore gate hardware might seem a small part of the overall offshore structures. Ultimately it can make your operators’ lives a lot easier, convenient, and safer by eliminating common risks such as trip hazards and impact.

Because offshore platforms and decks not only have to be safe but require a high level of operational functionality and efficiency. And that goes for the gates too.

Want to know more about how we can help you eliminate risks on offshore platforms? Read more in our other blogs below.

-

Gatemaster Offshore at Global Offshore Wind 2025

- Global Offshore Wind 2025, held on 17–18 June at ExCeL London, brought together industry professionals from across the offshore wind sector to share insights, explore innovations, and shape the future of renewable energy. For us, it was the ideal platform…

- Read More

-

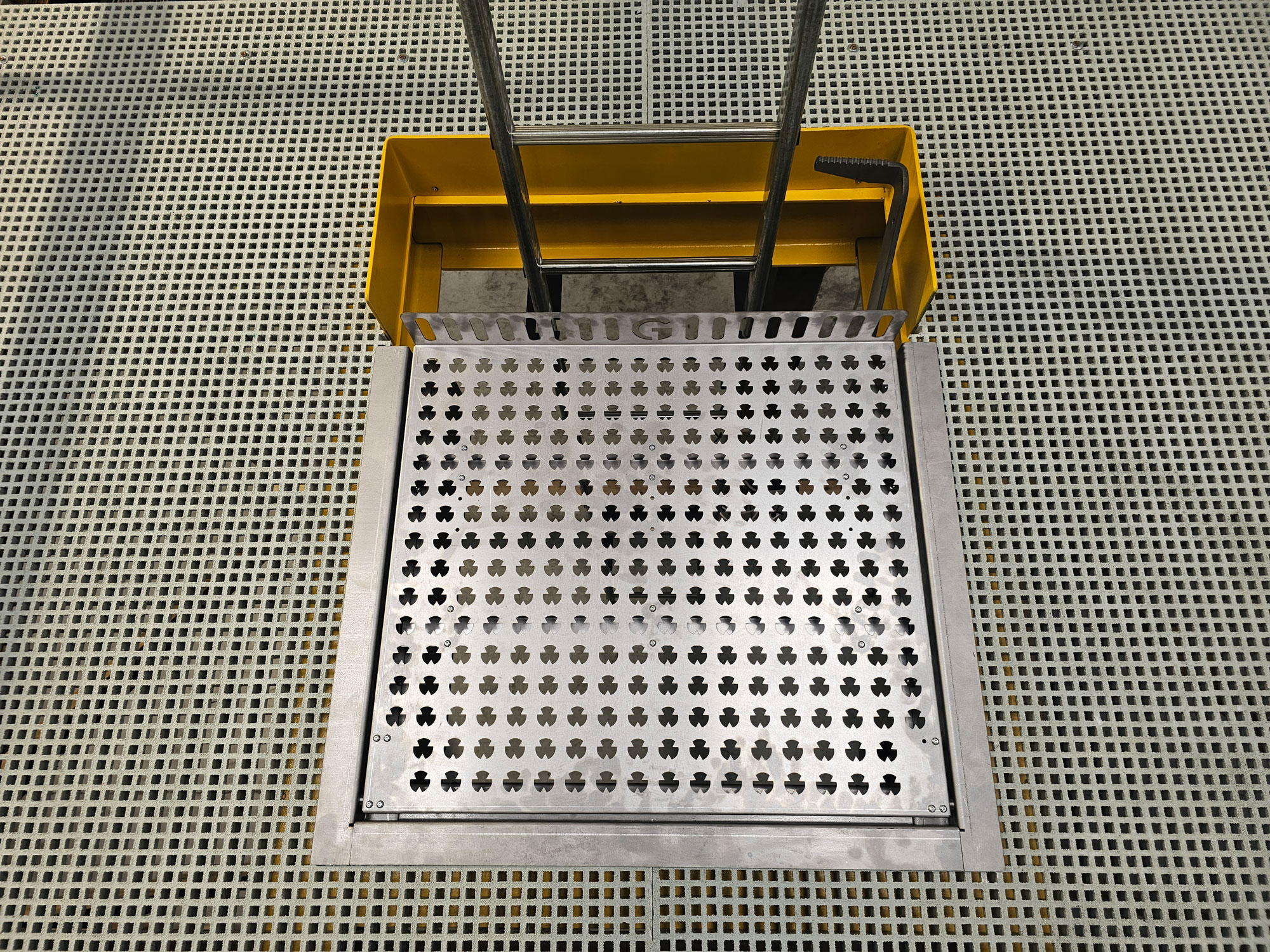

Reimagining Safety: Introducing Our New Internal Hatch for Safer Vertical Access

- Gatemaster Offshore launches the FOHO hatch system In offshore wind turbines, safety isn’t a bonus—it’s a necessity. Technicians working in tough isolated environments face a range of hazards daily, from high winds and wet surfaces to fatigue and confined spaces….

- Read More

-

Gatemaster Offshore at 2025 Key Industry Events

- Connecting with the Industry & Showcasing Offshore Access Solutions in 2025 As always the offshore wind sector is evolving rapidly in 2025, and at Gatemaster Offshore, we’re committed to staying at the forefront of innovation and reliability in access hardware….

- Read More